No kiln without kiln plates. Anyone who has taken classes or goes to an open studio knows that you’re supposed to trim your edges to avoid drips, that you need to glaze very carefully and that the bottoms of your pots need to be clean and clear of glaze. All of this to avoid that your glaze will drip onto the kiln plate. Because glaze that ends up on the plate and is fired at more than 1.200°C, that doesn’t come off! Many studios even have rules about repairing or replacing the kiln plate if it ends up being damaged because of your work.

Why protect the kiln plate?

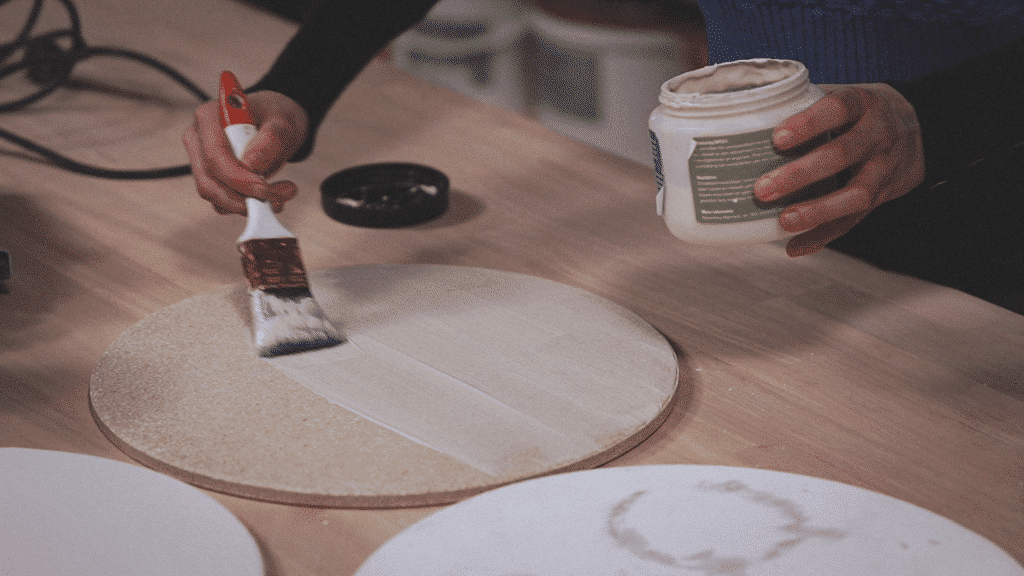

If you’ve bought your own kiln, start by giving your kiln plates a protective coating. You do this by applying three layers of kiln plate coating or batwash or kiln wash. The batwash is meant to ensure that, if any glaze does end up on the plate, you can get it off slightly easier without damaging the plate. First try to get the glaze off with a spatula or palette knife. If that doesn’t work, then you’ll need to use a grinder. Leaving the glaze on there is not an option, because during the next firing it would melt and run, so it might end up sticking to another pot.

Buying or making batwash

You can buy batwash ready-made in a pottery shop. It’s a liquid material that can be applied with a brush.

You can also make it yourself, with ingredients you can find in a pottery shop:

- 25% kaolin

- 25% molochite

- 50% alumina

Add water until you get a smooth paste.

Applying batwash to the plate

Apply the batwash to one side of the kiln plate with a broad brush. This first layer should not be too thick. Let it dry and then apply a second layer, making strokes in a different direction. Let it dry again and then add a third layer. Let it dry out fully before you use the kiln plate. Did you have to get some glaze off of the plate? Then make sure you re-apply batwash in that spot.